Light Weighting is a crucial approach for modern automotive manufacturers to balance efficiency, performance, and compliance with global emission standards. At Materials Info Consultancy Services, we specialize in guiding companies toward innovative solutions that reduce weight without compromising strength or safety.

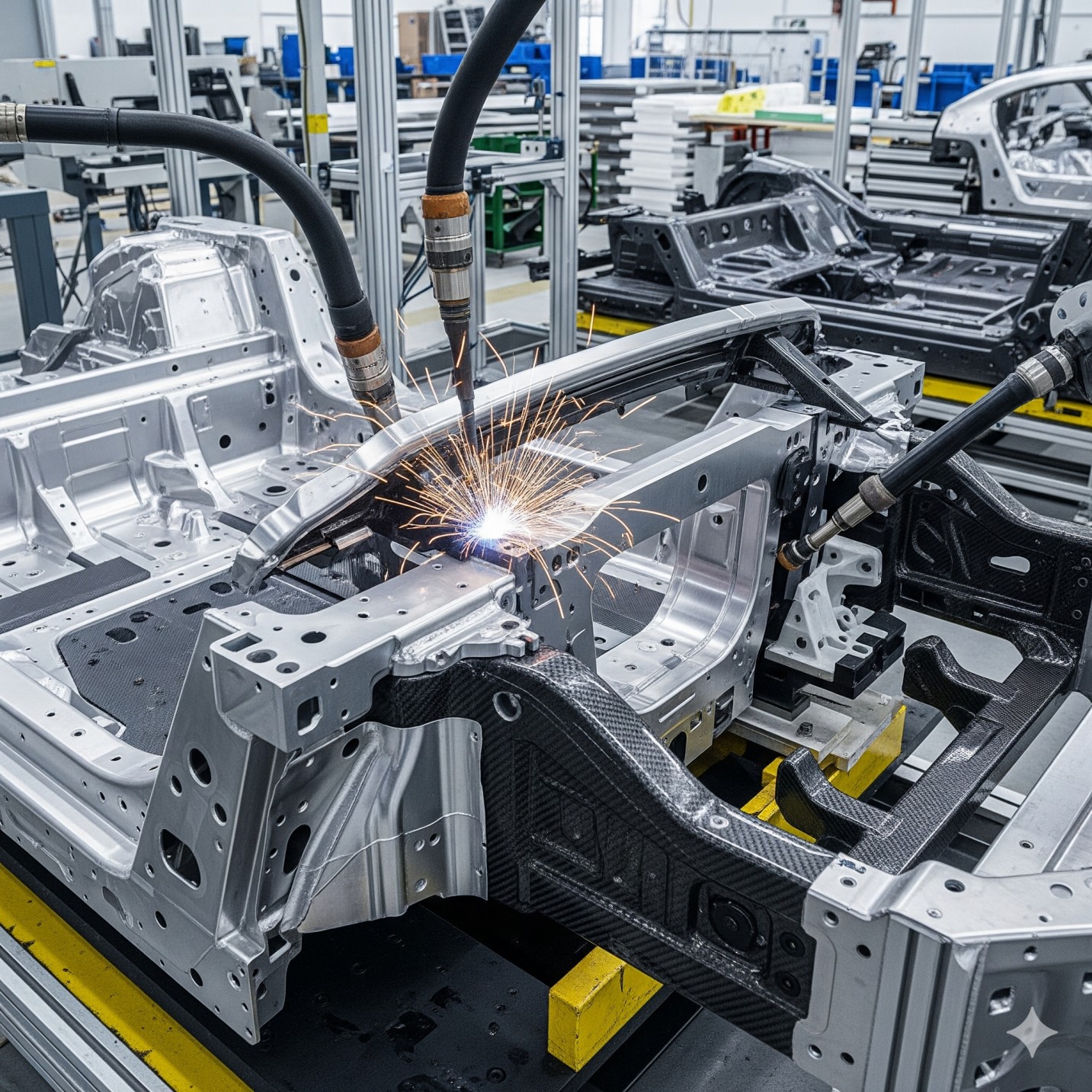

In today’s competitive automotive landscape, reducing vehicle weight is more than just a design goal—it is a necessity driven by stringent fuel efficiency norms, carbon dioxide emission limits, and increasing customer expectations for sustainable performance. Light Weighting, often referred to as vehicle mass reduction, involves the strategic use of materials and manufacturing processes that minimize overall weight while retaining durability and functionality. This approach begins at the earliest stage of product development, where the careful selection of materials such as aluminum, advanced steel, and composites plays a defining role. Hybrid constructions, for instance, combine aluminum with steel, while advanced techniques like hot stamping enhance the strength of components like chassis and structural parts, making them lighter yet more robust. At Materials Info Consultancy Services, we support clients not just in identifying the right materials, but also in evaluating manufacturing processes that align with cost, quality, and sustainability targets. Our expertise extends to benchmarking competitor samples, analyzing material and process combinations, and validating lightweight design strategies. The result is a holistic solution that helps clients achieve regulatory compliance, reduce costs, and enhance overall vehicle performance.

At Materials Info Consultancy Services, we take a complete lifecycle approach to Light Weighting solutions. Our team works closely with clients from the conceptual design phase through material and process selection, durability testing, and final validation. We not only help manufacturers identify the most suitable lightweight materials but also investigate potential failure points and provide corrective insights, ensuring designs are production-ready and reliable. Whether it is studying competitor benchmarks or integrating advanced hybrid construction methods, our support covers every stage of development. By combining technical expertise with a practical understanding of the automotive industry’s challenges, we enable organizations to introduce lightweight designs confidently into production. This ensures improved efficiency, compliance with international standards, and a competitive edge in delivering vehicles that are stronger, greener, and more cost-effective.