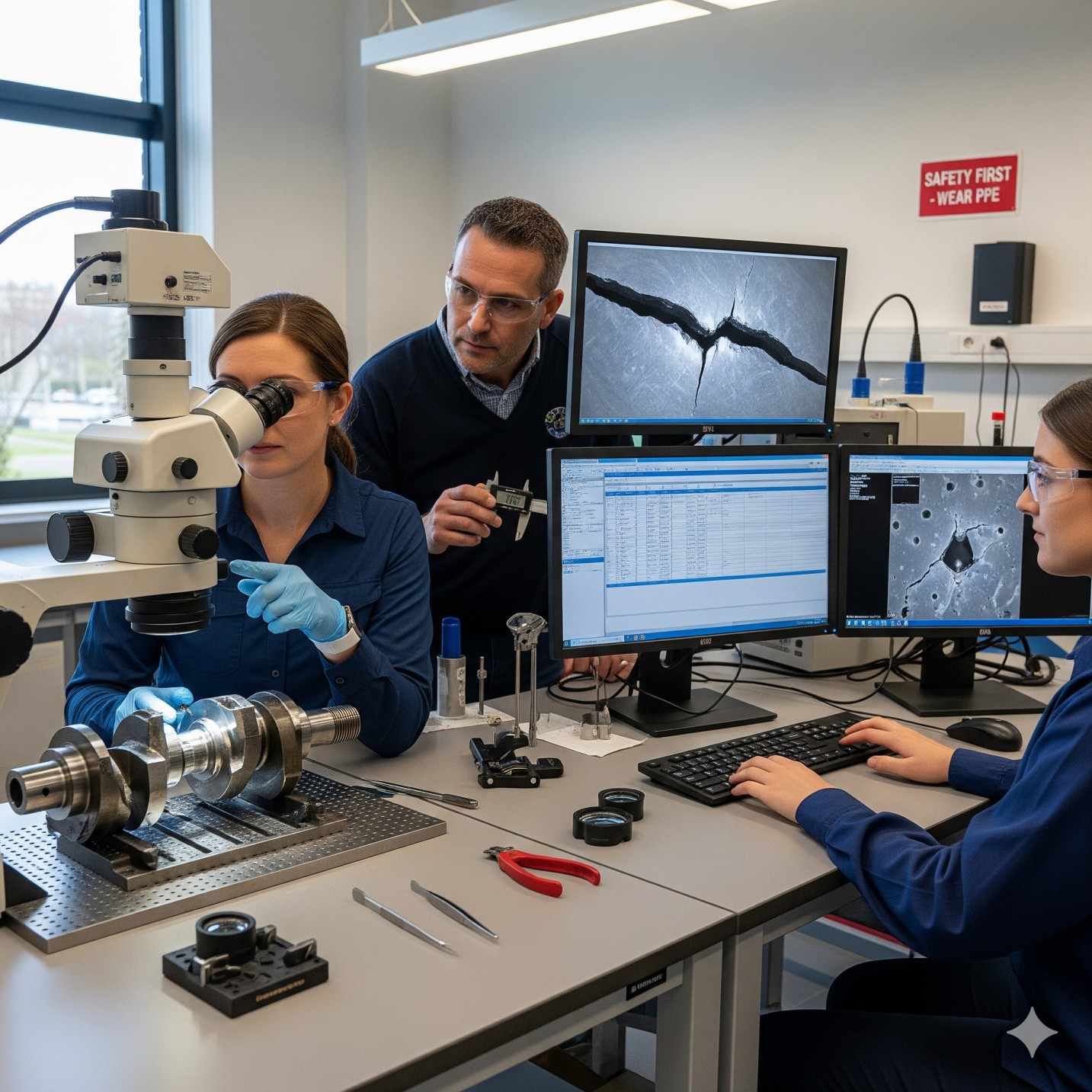

At Materials Info Consultancy Services, we understand that failures during manufacturing or product development can lead to costly delays and safety concerns. Our failure analysis services identify root causes and help implement effective corrective actions, ensuring robust and dependable outcomes.

Every product or manufacturing process carries inherent risks, with potential failure modes that can compromise performance, safety, and customer satisfaction. At Materials Info Consultancy Services, we approach failure analysis as a critical component of both product and process development. By thoroughly investigating failures, we determine whether they stem from design flaws or manufacturing inconsistencies, and then recommend targeted corrective measures. Our expert team uses systematic methodologies to assess risks, quantify potential impacts, and provide actionable insights that guide improvements. In product development, failure analysis helps prevent malfunctions, extend product life, and safeguard users against unforeseen hazards. In process development, our analyses ensure that production methods maintain high quality, achieve reliability, and avoid disruptions that lead to customer dissatisfaction or environmental risks. Our structured approach not only resolves current issues but also proactively identifies areas for enhancement, helping clients build resilient products and processes that stand the test of time. We are committed to turning setbacks into opportunities for innovation and reliability.

Failure analysis is not merely a troubleshooting tool—it’s a proactive strategy for ensuring long-term success. At Materials Info Consultancy Services, we support businesses by uncovering hidden risks and providing scientifically backed solutions to prevent recurrence. Our deep understanding of both design and process-related failures allows us to deliver customized recommendations that align with your production goals. Whether it’s improving product durability or refining manufacturing procedures, we help you mitigate risks that could result in downtime, customer complaints, or safety issues. Our services are designed to support innovation while promoting operational excellence. By addressing potential failure modes early in the development cycle, we assist organizations in making informed decisions that enhance efficiency, reliability, and customer trust. Choosing our failure analysis services means you’re investing in quality assurance and sustainable growth, with expert guidance every step of the way.